Melting and Elastic Effects of Polymer

Melting and Elastic

Effects of Polymer

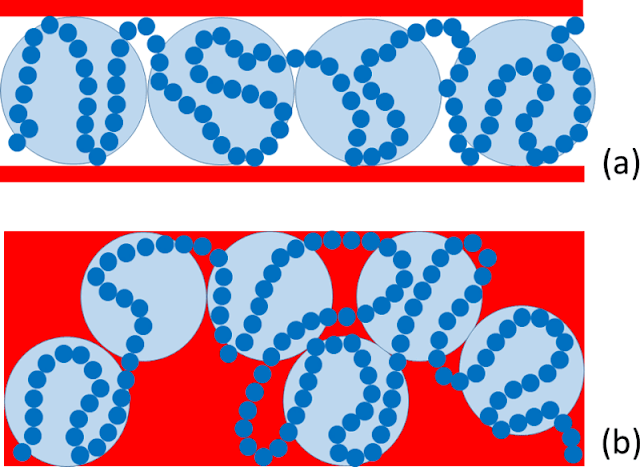

At the point when polymers are subjected to

shear in preparing tasks, the long chain of atoms show in them wind up

contorted. The atoms have a tendency to get rectified (situated) in view of

such shearing. The particles in the event has to be yet liquid will tend to

loop up again when the shearing procedure ends. The re-curling (at times

alluded to as unwinding) may not be finished when there is a fast cooling post-shearing.

The procedures of this uncoiling/re-curling lead to various wonders that are

typically called versatile

impacts. Extrude swell, sharkskin, dissolve crack, draw down, and

solidified in introduction are a portion of the imperative versatile impacts.

Extending, or drawing down the extrudate are

regular systems to repay strong extrudes for bite the dust swell. so that the extrude

can simply go through a measuring pass on. In spite of the fact that in this

procedure it is pointless for the two to be precisely adjusted, it ought to be

noticed that illustration down causes sub-atomic introduction.

This prompts quality upgrade in the stream

heading and quality decrease in bearings opposite to the stream which could

possibly be essential. On the off chance that the strong extrude has

fluctuating thicknesses. This is on account of shear rates and hence kick the

bucket swell are higher at the more slender segments. To guarantee that

expulsion rates don't change all through the cross-segment. More slender areas

may likewise have a shorter bite the dust length to build the extrude swell

considerably further. The circumstance is more muddled amid the expulsion of pipe

and tubing. Since the extrude is frequently expanded by the measurements of

an estimating kick the bucket. For this situation, the presumption is that that

the divider thickness will extend to the kick the bucket swell fitting to the

shear evaluated utilized. After the rising up out of the extruder bite the

dust. Be that as it may there will be a decrease in the divider thickness

corresponding to the swelling. where the expansion is the proportion of the

estimating kick the bucket measurement to the outside distance across of the expulsion

pass on.

Mark

Klinger

Program Manager | Polymer Catalysis 2018

Kemp House, 152 City Road

London EC1V 2NX

United Kingdom

Program Manager | Polymer Catalysis 2018

Kemp House, 152 City Road

London EC1V 2NX

United Kingdom

Comments

Post a Comment