Modified Oleffin Polymerization by Strong Metal–Metal Cooperative Effects

Poly olefins are created today chemically on a tremendous

scale and the made polymers discover use in everything from counterfeit

appendages and sustenance/therapeutic bundling to car and electrical parts

and greases. In spite of the fact that polyolefin monomers are commonly

shoddy (e.g., ethylene, propylene, α-olefins), the subsequent polymer

properties can be drastically tuned by the specific polymerization impetus

utilized, and mirror a rich exchange of macromolecular science, materials

science, and physical science. For instance, direct low-thickness

polyethylene (LLDPE), created by copolymerization of ethylene with straight

α-olefin co monomers, for example, 1-butene, 1-hexene, or 1-octene has

little. however huge levels of short alkyl branches (C2, C4, C6) along the

polyethylene spine is a vital innovation material because of extraordinary

rheological and mechanical properties. In 2013, the aggregate world

polyolefin generation was roughly 211 million metric tons of which around 11%

was LLDPE. polyolefins were delivered

utilizing poorly characterized yet very dynamic heterogeneous impetuses made

out of upheld bunches 4 or 6 species (normally halides) initiated by aluminum

alkyls. In 1963, Karl Ziegler and Giulio Natta got the Nobel Prize for these

revelations. Starting in the late 1980s

Another age of gathering 4 atom based homogeneous olefin

polymerization impetuses rose up out of revelations by Walter Kaminsky. A

group drove by James Stevens at The Dow Chemical Company, this Laboratory at

Northwestern University, and a large group of skilled gatherings in Germany,

Italy, Japan, the United Kingdom, and the United States. These new

"single-site" impetuses and their actuating co catalysts were

obviously better characterized and all the more sanely tunable regarding

structure, component, thermodynamics, and impetus movement and selectivity

than at any other time conceivable. A blast of research progresses prompted

new impetuses, co catalysts, more profound robotic comprehension of both the

homogeneous and heterogeneous frameworks, macromolecules with drastically

changed properties, and substantial scale modern procedures.

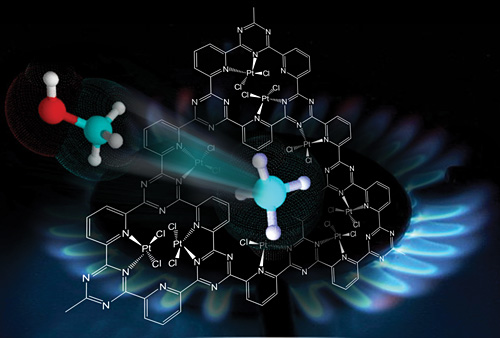

It is significant that numerous metalloenzymes utilize different dynamic focuses working in close synergistic vicinity to accomplish high movement and selectivity. Such proteins were the motivation for the exploration talked about in this Account, concentrated on the properties of multimetallic olefin polymerization impetuses. Here we talk about how alterations in natural ligand engineering, metal metal vicinity and co catalyst can drastically adjust polyolefin atomic weight, branch structure, and specifically for olefinic co monomer enchainment. We initially talk about bimetallic impetuses with indistinguishable gathering 4 metal focuses and after that heterobimetallic frameworks with either aggregate 4 or gatherings 4 + 6 synergist focuses. We look into the polymerization properties of the bimetallic impetuses with their monometallic analogues featuring stamped agreeable enchainment impacts and unordinary polymeric items conceivable by means of the proximate reactant focuses. Such multinuclear olefin polymerization impetuses display the accompanying particular highlights: (1) remarkable levels of polyolefin spreading; (2) improved enchainment selectivity for direct and hampered α-olefin comonomers; (3) upgraded polyolefin tacticity and atomic weight; (4) irregular 1,2-addition region chemistry for styrenic monomers; (5) altered chain exchange energy, for example, M-polymer β-hydride exchange to the metal or approaching monomer; (6) LLDPE amalgamation with a solitary binuclear impetus and ethylene.

For More Details Contact

Best Regards

Mark Klinger

Program Manager | Polymer Catalysis 2018

|

Comments

Post a Comment